To get to the Vises main page click the Vises link directly, it is not in the dropdown menu.

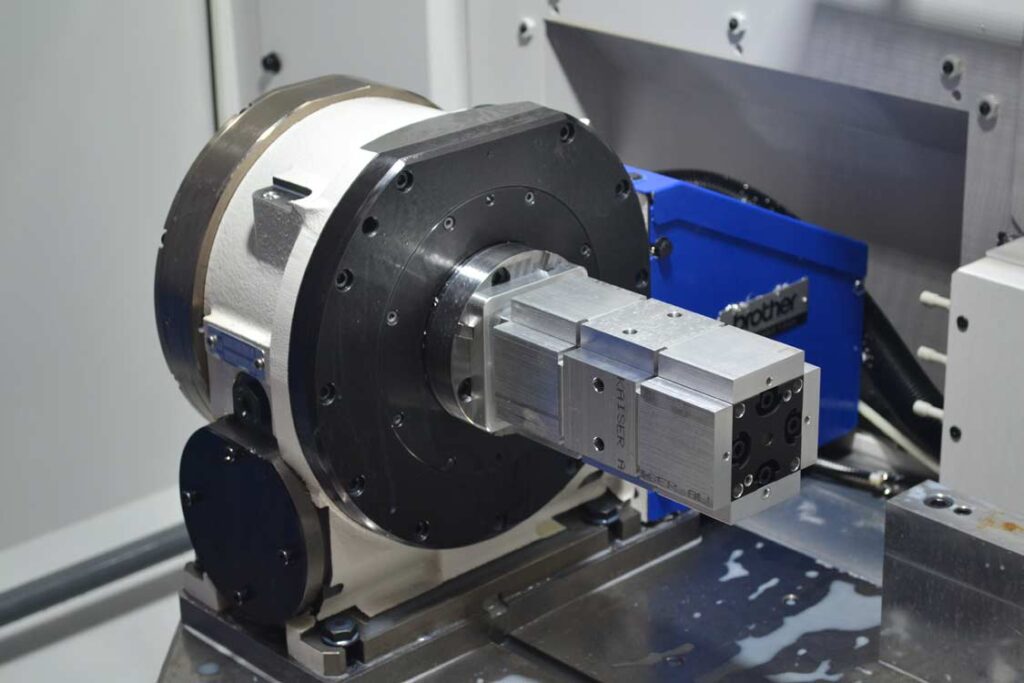

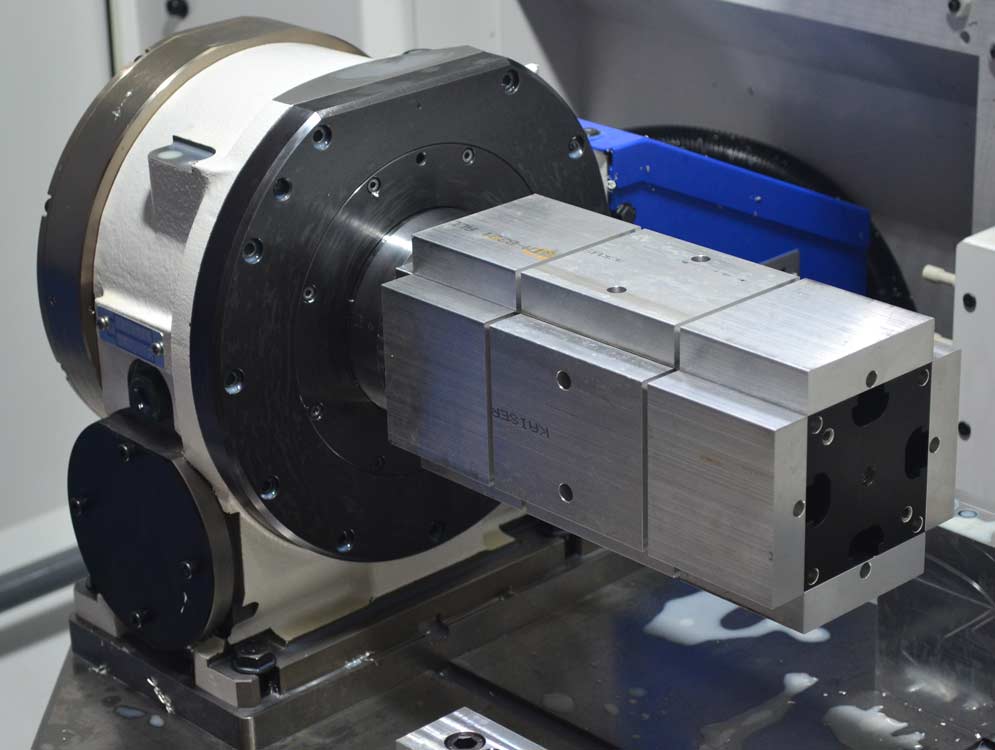

To mount one of our vises to your rotary table all you need to do is mount a drive platen to your rotary and install a drive plate on your vise. If you don’t wish to use a tailstock then mount the vise to the drive platen, install the bolt through the drive platen and into the vise, and torque the 3/8-16 to 25 lb-ft and the 1/2-13 to 40 lb-ft. If you do want to use a tailstock then install it so that you can just clear the center as you rotate the vise away from the drive platen after pulling it tight against the tailstock center. Once the tailstock is bolted tight to the table, mount the vise to the drive platen and tighten the tailstock to the appropriate amount.

Mounting the vise with a tailstock is the most accurate and stable method of doing so. While mounting directly to the rotary is fast, compact, and convenient I am seeing the end of some vises move up to .001″ after making a batch of parts. How much depends on how hard I machined the parts, one vise only moved .0002″. I suspect the error lies in the drive plate and am working to improve this. If you need tenths repeatability then use the inside stations only, or mount using a tailstock, where the vises end positional accuracy has always been as good as the tailstocks.

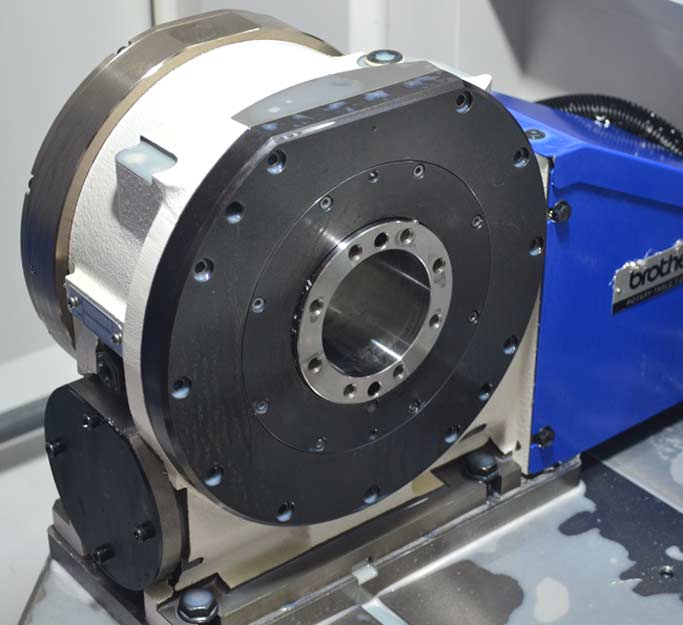

Above is a rotary table without a platen.

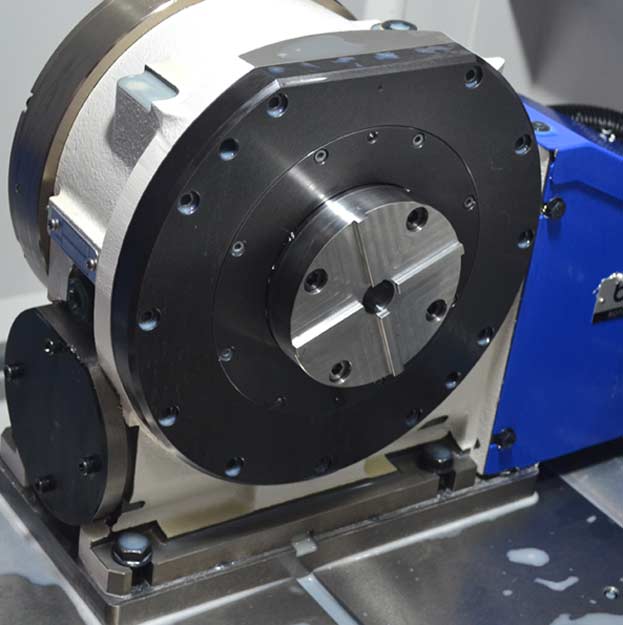

This photo shows a drive platen mounted to the rotary table. Make sure your brake is engaged when tightening the bolts.

These 2 photos show a 2″ standard jaw vise and a 3″ standard jaw vise mounted to a rotary table without using a tailstock.