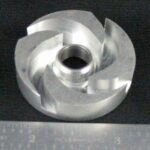

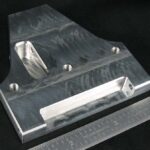

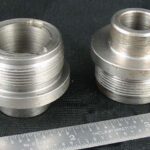

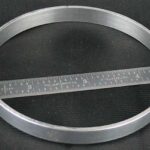

For the past 20 years we have made our own products as well as doing production machining for a local business. We specialize in production machining of smaller precision parts with run sizes of 500 parts or more but are fully capable of smaller runs or one-off parts. Besides the parts displayed on this website, the photos below are some of the parts I have made over the years. All current machining is done on a new Brother R650 vertical CNC milling machine with a 4th axis on each table and a work envelope of 22″ x 15.75″ x 12″ with the 4ths in place. It is a high speed production mill with a rotating table so I can swap parts on one table while the machine is making parts on the other. I have several videos showing how fast and efficient this machine is, here is one of the better ones.

Over the years most of the parts I have made could not be photographed and certainly not the most interesting ones. With this in mind please don’t limit what I can do to what I show with these photos. The top gallery is more recent with the lower one much older.

We are a Columbia River Gorge machine shop, Hood River Oregon machine shop, White Salmon Washington machine shop, Bingen Washington machine shop, and The Dalles Oregon machine shop, keywords for searches. My background involves all aspects of plasitc injection molding with an emphasis on designing and making the molds, molds for other processes, production machining parts made from many metals including aluminum and steel, plastic, ceramic, quartz, stone, and product development. While I am still capable of doing most of these things my current focus is on production machining tighter tolerance parts at the lowest cost possible due to the fact that the markets I have been serving are quite cost sensitive. For reference the parts I make commonly have feature tolerances of +/-.0002″ and positional tolerances of +/-.001″ or less with demanding cosmetic needs. If you have production machining needs that may fit my capabilities then please call or email.