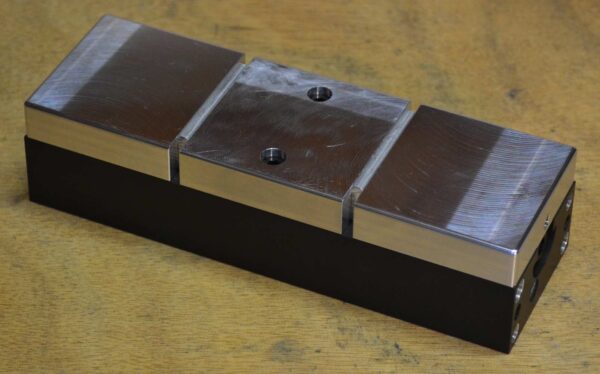

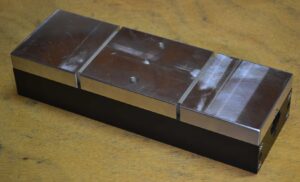

The vise body is made from 6061-T6 aluminum with a .003″ thick Type III anodized finish. All holes used are machined after anodizing and the 8-32 mounting holes are wire inserted .246″ deep. The center jaw is located with (4) 3/16″ x .125″ tall dowel pins and held down with (2) 8-32 SHCS. The moving jaws have the traditional dovetail wedge interface with a spring plunger from the back holding them in place. The jaw carriers extend 3/8″ under the fixed jaw and are .005″ below the vise bed to keep chips out. The way that double station vises work pulling the moving jaws together against the fixed jaw transfers very little load to the vise body. The lead screw is a 4″ long 1/4-20 SHCS. There are (4) .25″ x .4″ deep slip-fit reamed holes in the bottom and (2) counterbored holes down the middle for 1/4″ SHCS to locate and hold the vise in place on pallets. All materials are made in the U.S.A. and good quality.

For more information please watch some of my videos where I both show the features of these vises and make parts with them.

https://youtu.be/8NgjtuJaItg shows them in use without a tailstock.

https://youtu.be/a5k4GA582PA is an overview of the vises and shows how fast you can swap them with a pneumatic tailstock to keep the spindle spinning.

Skyler (verified owner) –

Excellent little vise for second ops on smaller parts. The perfect compliment to larger, more expensive, soft jaws. Solid design that is simple, manufactured nicely and at a great price point. I’m almost through my first few sets of jaws and will be buying more.